Products

Moveable Nitrogen System

The essential component of intelligent system engineering, where moveable nitrogen systems are outfitted with manufacturing devices, monitoring devices, control devices, etc. Nitrogen Capacity: 1-200Nm³/hr Nitrogen: 99-99.999% Nitrogen: 0.1-0.7Mpa (150-200Bar Refilling Pressure can be offered)

Send Inquiry

Product Description

China Moveable Nitrogen System Manufacturers

China Moveable Nitrogen System Suppliers

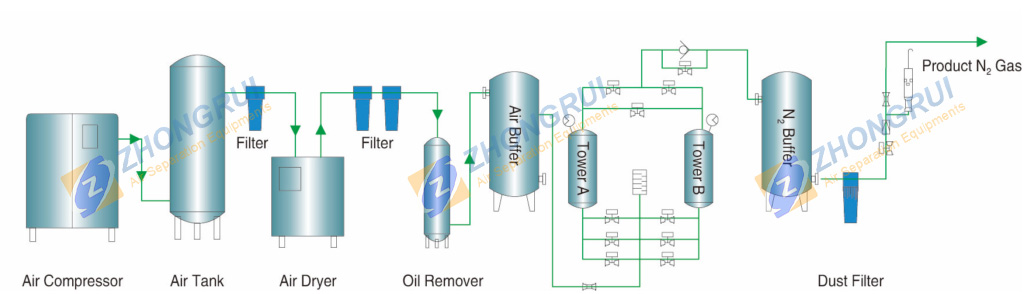

A moveable nitrogen system from China factory is designed and manufactured according to PSA technology. A moveable nitrogen system uses an imported high-quality carbon molecular sieve (CMS) as an adsorbent to separate air and produce high-purity nitrogen by pressure swing adsorption (PSA) at room temperature. Usually, two adsorption towers are connected in parallel, and the inlet pneumatic valve is controlled by the imported PLC to operate automatically. The pressurized adsorption and decompression regeneration are carried out alternately to complete the nitrogen and oxygen separation and obtain the required high-purity nitrogen.

1.Parameter (Specification) of Moveable Nitrogen System manufacturer

| Model | Nitrogen Capacity | Power | Nitrogen Purity | Feed Air Pressure | Nitrogen Pressure |

| ZR-3 | 3Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-5 | 5Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-10 | 10Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-15 | 15Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-20 | 20Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-30 | 30Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-40 | 40Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-50 | 50Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-60 | 60Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-80 | 80Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-100 | 100Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-150 | 150Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-200 | 200Nm³/hr | 0.1KW | 99-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

Remark: For more models and specifications please contact us.

Moveable nitrogen systems are suitable for the petroleum industry, natural gas industry, chemical industry, and other relative industries, which have outstanding features of strong adaptability, flexible mobility, etc.

Vehicle-mounted moveable nitrogen systems can be applied in exploitation, purging, replacement, emergency rescue working, attenuation of flammable gas or liquid, etc. in the petroleum and natural gas industry. There are low pressure, medium pressure, and high-pressure series of nitrogen systems.

Moveable nitrogen systems are the core place of intelligent system engineering, where are equipped with production devices, monitoring devices, control devices, etc. According to customer requirements, the container design is divided into following several parts:

1) Nitrogen generation system

2) Nitrogen booster system

3) Fire extinguishing system

4) Lighting system

5) Ventilation system

6) Pipeline system

7) Power distribution system with generator sets

8) Alarm system

9) Automatic integrated system

2.Flow Chart of Moveable Nitrogen System Manufacturer

3. Features of Moveable Nitrogen System

1) Container type makes it convenient for installation, operation, lifting, and transportation.

2) Design strictly according to customer on-site working conditions.

3) Operate automatically, and DCS control can be supplied.

4) Both electric drive and generator drive can be used, convenient for field operations.

5) Professional solutions can be supplied for other special requirements from customers.

4. Applications and Support of Moveable Nitrogen System

Electronic industry: nitrogen protection during the production of semiconductors and electronic components.

Heat treatment: nitrogen protection, nitriding, bright annealing, anti-oxidation for various kinds of industrial furnaces.

Food and beverage industry: use for nitrogen-filled packing, grain storage, vegetables and fruits preservation, wine conservation, etc.

Chemical industry: nitrogen blanketing, replacement, cleaning, pressure transmission, agitation of chemical reactions, nitrogen protection of chemical fiber production, etc.

Petroleum and natural gas industry: petroleum refining, nitrogen purging and leakage detecting of vessels and pipes, oil extraction with filling nitrogen.

Pharmaceutical industry: nitrogen-filled packing, transportation, and storage of APIs (Active Pharmaceutical Ingredients), Chinese & Western medicines. Corrosion prevention & vermin prevention of Chinese herbal medicine, etc.

Cable industry: nitrogen protection during the production of cross-linked cables.

Powder metallurgy: nitrogen protection when sintering powder & magnetic materials.

Rubber/tire industry: use nitrogen to keep pressure on tires and tire vulcanization, to improve product quality.

Synthetic fiber industry: nitrogen protection during the fiber drawing process

Aluminum processing industry: nitrogen protection for smelting & forging of aluminum materials, manufacturing of aluminum products, rolling of aluminum foil, etc.

5. Shipment of Moveable Nitrogen System Manufacturer

Hot Tags: Moveable Nitrogen System, Manufacturers, Suppliers, Buy, Customized, Factory, , Made in , Price