Products

Nitrogen Gas For SMT

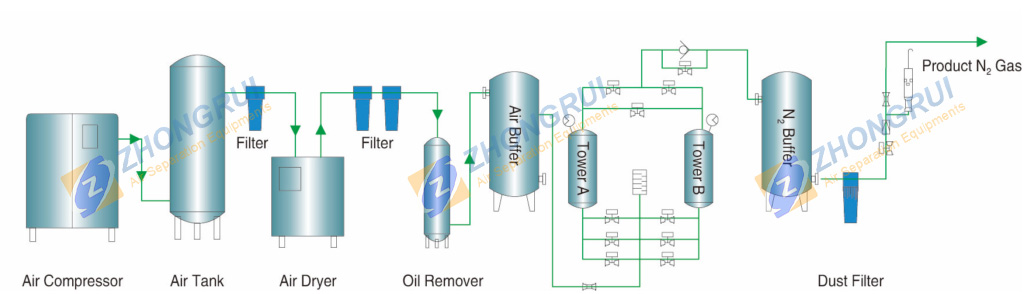

PSA nitrogen generator belongs to one of the ambient temperature industrial nitrogen production modes. Its principle is to use carbon molecular sieve as adsorbent, using the principle of pressurized adsorption and depressurized desorption to adsorb and release nitrogen from the air. Nitrogen Capacity: 1-1000Nm³/hr Nitrogen Purity: 99.5%-99.999% Nitrogen Pressure: 0.1-0.7Mpa (adjustable)

Send Inquiry

Product Description

Nitrogen Gas

Nitrogen Gas For SMT Manufacturers

Maximizing efficiency and reducing costs is a priority for the majority of manufacturing & processing companies, regardless of if they package food or utilize surface mount technology (SMT) for electronics manufacture. If you use nitrogen gas as part of the SMT manufacturing process, perhaps for selective soldering, wave soldering, or even or reflow ovens, you should consider the savings you can make on your nitrogen costs. The easiest way to save on your SMT nitrogen costs is to become your own nitrogen gas supplier by investing in a nitrogen gas nitrogen generator for SMT.

1.Parameter (Specification) of high-quality Nitrogen Gas For SMT

| Model | Nitrogen Capacity |

Power | Nitrogen Purity | Feed Air Pressure |

Nitrogen Pressure |

| ZRO-3 | 3Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-5 | 5Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-10 | 10Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-15 | 15Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-20 | 20Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-30 | 30Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-40 | 40Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-50 | 50Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-60 | 60Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-80 |

80Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-100 |

100Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-150 |

120Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-200 |

150Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-300 |

200Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-400 |

300Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-500 |

500Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-600 |

600Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-800 |

800Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-0.7Mpa |

| ZRO-1000 |

1000Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-0.7Mpa |

Remark: For more models and specifications please contact us.

PSA (Pressure Swing Adsorption) is an advanced gas separation technology, which has an irreplaceable position in the field of current on-site gas supply. PSA nitrogen generators for SMT use compressed air as raw materials and carbon molecular sieves (CMS) as adsorbents to get high purity nitrogen based on the principle, which is pressure swing adsorption under normal temperature. PSA nitrogen generators for SMT use two parallel adsorption towers, which are automatically running with pneumatic valves controlled by PLC, alternatively, adsorb under pressure and regenerate without pressure, to separate nitrogen and oxygen, and get the final required high purity nitrogen gas continuously.

2.Introduction of advanced Nitrogen Gas For SMT Suppliers

3. Features of high-quality Nitrogen Gas For SMT manufacturer

1) The equipment adopts the brand-newly-designed filling technique, extending service life of molecular sieve to more than 10 years.

2) Special bypass design ensures lower energy consumption and larger effects.

3) Imported pneumatic valves guarantee much more stable performance.

4) Computer operation, simple technical design, easy maintenance.

5) Installation is simple. Not require special foundation, just need flat ground.

4. Applications and Support of advanced Nitrogen Gas For SMT

Using nitrogen gas in reflow soldering and wave soldering can effectively inhibit the oxidation of solder tin, enhance the welding wettability, speed up wetting, reduce solder balls and avoid/reduce bridge connection defects, to get high welding quality. Requested nitrogen purity should be more than 99.99%. Manufacturing process of semiconductor devices: crystal growth, dry etching of plasma, lithography, annealing, connecting, sintering, etc. And producing process of electronic components: color picture tubes, large scale integrated circuits, liquid crystals and silicon pellets, etc., all can use nitrogen as protective and carrier gas.

5.Shipment of Nitrogen Gas For SMT manufacturer

Hot Tags: Nitrogen Gas For SMT, Manufacturers, Suppliers, Buy, Customized, Factory, China, Made in China, Price

For the users of PSA nitrogen generator, nitrogen purity must be an indicator that everyone is concerned about, after all, to judge whether the output gas is qualified or not, the focus is on gas purity; however, in fact, if you want to maintain the intended purity after a long period of use, you can only reduce the flow rate of the nitrogen generator while keeping the pressure unchanged. The reason for doing so is that the efficiency of the molecular sieve decreases over a long period of time. This is because the water and oil in the raw material air will pollute the carbon molecular sieve, although the air treatment system will do layers of air filtration, but can not remove 100% of the water and oil in the air; once the water and oil into the molecular sieve, it is easy to be adsorbed by the molecular sieve; over time, it will affect the pore size of the carbon molecular sieve; reduce the efficiency of the molecular sieve, so that the purity of nitrogen production decreases.