Products

Nitrogen Generation Unit For Laser Cutting

Our on-site Pressure Swing Adsorption (PSA) Nitrogen Generating Systems enable you to generate high purity nitrogen, used in assisting, high-pressure metal cutting and beam path purge, while virtually eliminating nitrogen gas evaporation loss as well as recurrent delivery and rental charges. Nitrogen Capacity: 1-300Nm³/hr Nitrogen Purity: 99.5%-99.999% Nitrogen Pressure: 0.1-3.5Mpa (Pressure can be custom-made)

Send Inquiry

Product Description

Nitrogen Generation

Laser Cutting

1.Parameter (Specification) of high-quality Nitrogen Generation Unit for Laser Cutting

| Model | Nitrogen Capacity |

Power | Nitrogen Purity | Feed Air Pressure |

Nitrogen Pressure |

| ZRO-3 | 3Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-5 | 5Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-10 | 10Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-15 | 15Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-20 | 20Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-30 | 30Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-40 | 40Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-50 | 50Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-60 | 60Nm³/hr |

0.1KW | 99.5-99.999% | 0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-80 |

80Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-100 |

100Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-120 |

120Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-150 |

150Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-200 |

200Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-3.5Mpa |

| ZRO-300 |

300Nm³/hr |

0.1KW |

99.5-99.999% |

0.8-1.0Mpa |

0.1-3.5Mpa |

Remark: More models and specifications please contact us.

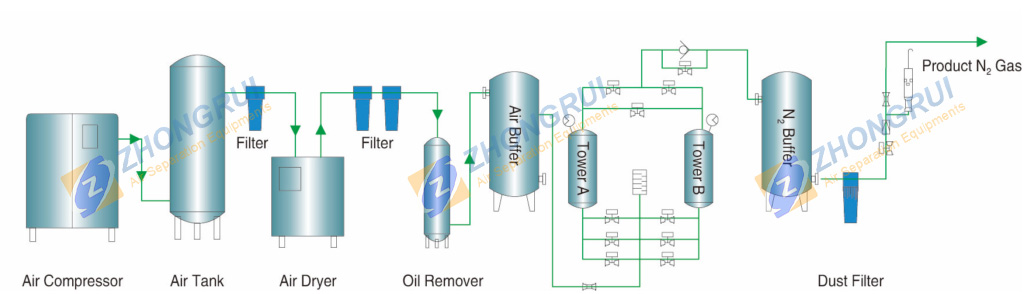

PSA (Pressure Swing Adsorption) is an advanced gas separation technology, which has an irreplaceable position in the field of current on-site gas supply. PSA nitrogen generators use compressed air as raw materials and carbon molecular sieves (CMS) as adsorbent to get high purity nitrogen based on the principle, which is pressure swing adsorption under normal temperature. In general, use two parallel adsorption towers, which are automatically running with pneumatic valves controlled by PLC, alternatively adsorb under pressure and regenerate without pressure, to separate nitrogen and oxygen, and get final required high purity nitrogen gas continuously.

2.Introduction of advanced Nitrogen Generation Unit for Laser Cutting

3. Features of Nitrogen Generation Unit for Laser Cutting

1) The equipment adopts the brand-newly-designed filling technique, extending service life of molecular sieve to more than 10 years.

2) Special bypass design ensures lower energy consumption and larger effects.

3) Imported pneumatic valves guarantee much more stable performance.

4) Computer operation, simple technical design, easy maintenance.

5) Installation is simple. Not require special foundation, just need flat ground.

4. Applications of low-price Nitrogen Generation Unit for Laser Cutting

There’s an alternative to purchasing nitrogen regularly.

With these units, nitrogen with purities from 95 to 99.999% can be produced for a fraction of the market price of Nitrogen, right in your own facility. Other added benefits of our Nitrogen Generator are increased workplace safety and security, while eliminating the need for hazardous storage areas.

Since the systems operate entirely automatically in direct response to demand, downtime due to late deliveries, or unexpected empty gas cylinders, becomes a thing of the past. Companies using N2 for cutting assist or beam path purge can realize immediate benefits from our on-site Nitrogen Generating System.

5.Shipment of discount Nitrogen Generation Unit for Laser Cutting

Hot Tags: Nitrogen Gas For SMT, Manufacturers, Suppliers, Buy, Customized, Factory, China, Made in China, Price